Tesla has initiated a recall of 271 Model S and Model X in China over issues with the vehicles’ seat belts and camera installation.

The recall affects 234 Model S and Model X vehicles that were produced between February 5 and May 16, 2023. During the vehicles’ production or after-sale service, the first-row seat belts and pretensioners were disassembled, and during reinstallation, the parts may not have been properly connected to the pretensioner anchors according to specifications.

China’s State Administration for Market Regulation (SAMR) noted that in the event of a crash, the affected Model S and Model X’s seat belts may not function correctly as restraints. This, of course, creates a safety risk.

To address the issue, Tesla will inspect the affected vehicles’ first-row seat belts and pretensioner anchor points at no cost to the owner. If any connections are found to be non-compliant with design specifications, they will be reinstalled according to the correct specifications. If needed, the entire seat belt assembly will be replaced.

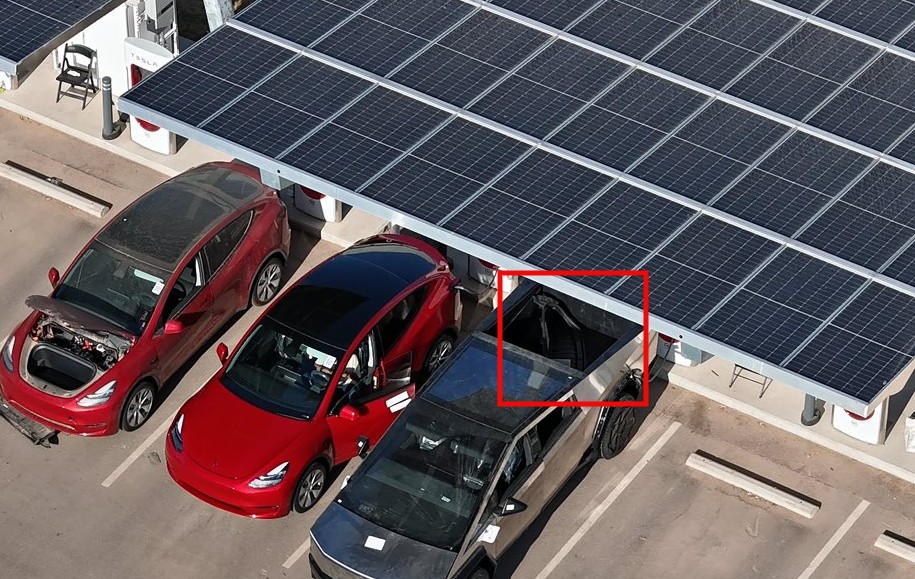

The recall also covers 37 Model S and Model X that were manufactured between January 17 and July 11, 2023. These vehicles have issues with their front view camera installation, as they do not meet pitch angle design requirements. This could lead to improper functioning of active safety features and driver alerts, creating a safety risk.

To fix the affected vehicles’ camera fault, Tesla will conduct free checks on the front view camera’s pitch angle at zero cost to owners. If any camera angles are not according to specifications, they will be corrected.

Tesla China imports the Model S and Model X from the Fremont Factory, since Gigafactory Shanghai only manufactures the Model 3 sedan and Model Y crossover. This facility is the company’s largest factory by volume globally, with an annual production capacity of over 750,000, as per Tesla’s Q2 2023 Update Letter. Tesla also sold a total of 64,285 China-made vehicles in July, including exports and domestic deliveries, as per data from the China Passenger Car Association (CPCA).

Don’t hesitate to contact us with news tips. Just send a message to simon@teslarati.com to give us a heads-up.