A significant part of Tesla’s business relies heavily on the durability and longevity of its battery packs, and in the spirit of disruptive innovation, the Silicon Valley-based company has continued to make improvements to its battery technology to make them more durable and more efficient. Tesla was able to achieve this through several ways, one of which was discussed in a recently published patent application.

It is pertinent for battery packs, particularly those that are used for energy storage, to be robust enough that they last for a very long time. To accomplish this, battery packs must be able to handle multiple charge and discharge cycles on a regular basis. They must also be able to weather faults in the system, including those that may cause damage to the actual cells in the pack itself.

Such a system was outlined by Tesla in a patent simply titled “Energy Storage System.” Explaining its rationale, the Silicon Valley-based company stated that “cells and other components in a pack generate heat during operation, both during the charging process to store the energy and during the discharge process when energy is consumed.” Tesla further explains that “when the cells fail, they typically release hot gases. These gases may impact the integrity of other cells in the pack and may cause substantial damage to the functional cells which have not failed.”

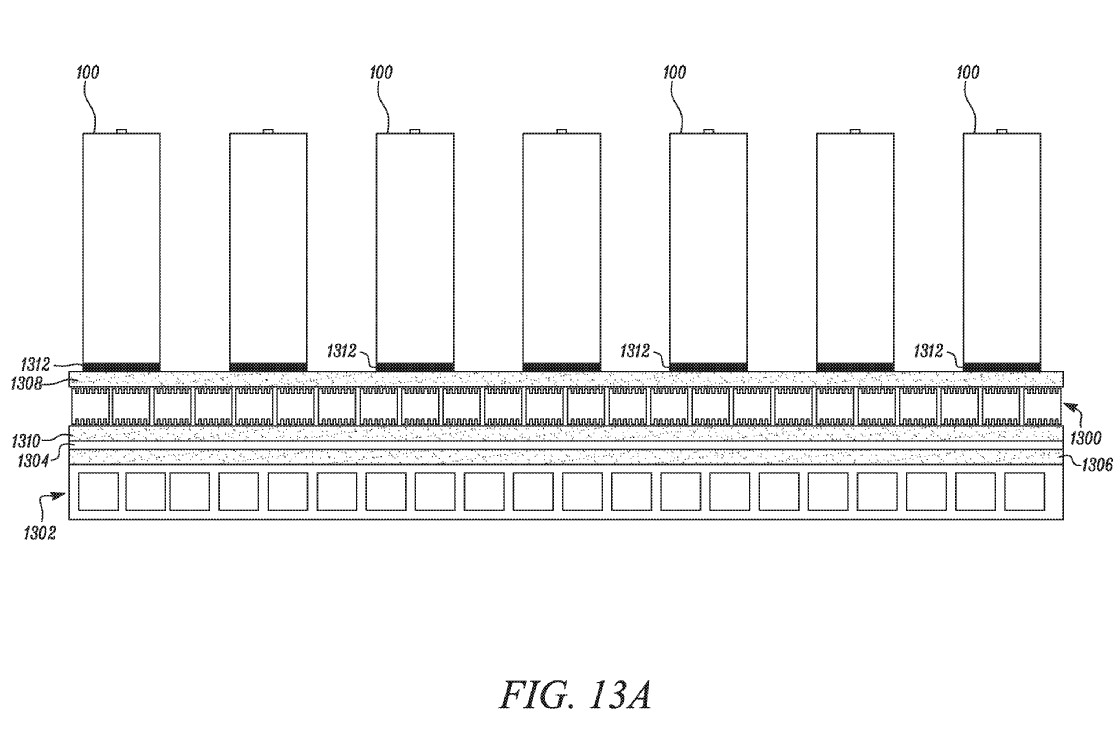

With this in mind, Tesla maintains that there is a need to develop an “improved energy storage system” that will be capable of reducing or removing “one or more of the issues mentioned.” Tesla’s patent describes two strategies that could improve its battery packs. One of these involves the use of a novel system that utilizes a cold plate, which could help remove heat generated by the battery pack during use. Heat pipes may also be used together with a cold plate to achieve this purpose.

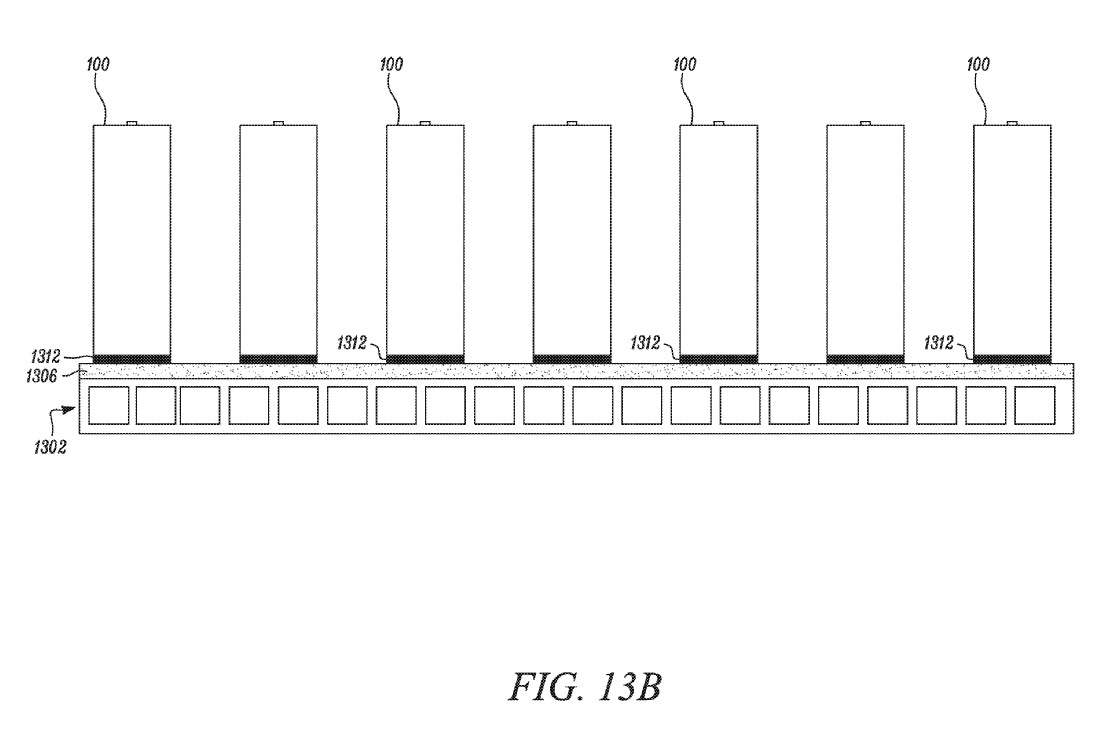

“In certain embodiments, a cold plate (which provides liquid cooling) may be in thermal connection with the battery cells 100 to further remove heat generated during system use. The cold plate may be in direct thermal contact with the battery cells 100 or, alternatively, one or more layers and/or features may be between the cold plate and the battery cells 100. In certain embodiments, the battery cells 100 are in contact with one or more heat pipes to remove excess heat disposed under the battery cells. A cold plate is disposed below the heat pipe or pipes (on the side of the heat pipe away from the battery cells 100) that helps dissipate the heat contained in the heat pipe.”

“In certain embodiments, the cold plate may be in thermal contact with one side of the cells without any heat pipes disposed between the cells. The cold plate may physically consist of a single plate or multiple plates that are thermally connected to the cells and/or one another. In other embodiments, one or more heat pipes are disposed between the battery cells 100 and a cold plate is disposed below the battery cells 100. The heat pipes and the cold plate may be in thermal connection with one another.”

Apart from the use of cold plates, Tesla also described a battery pack with regions that are designed to give way when mechanical failures happen. By using such a system, the majority of the cells in a battery pack become protected even if some cells were to fail.

“The top plate includes one or more weak areas above the one or more battery cell. The weak areas are regions that have less integrity and thus, where mechanical failure is more likely to occur if a battery cell releases gas. These regions may be physically weaker areas compared to the surrounding areas and may rupture when pressure builds up due to a failed cell. Alternatively, the weak areas may be chemically weaker and preferentially rupture when exposed to the caustic gases released by a failed battery cell. The weak areas may also fail due to a combination of physical and chemical weakening.”

The full text of Tesla’s Energy Storage System patent could be accessed here.

Tesla’s focus on battery integrity in its recently published patent application suggests that the Silicon Valley-based company is looking to develop packs that are capable of lasting a very long time. Such improvements have been teased before, especially in a paper released by Tesla lead battery researcher Jeff Dahn and members of the Department of Physics and Atmospheric Science at Dalhousie University. The cells described in the paper are capable of lasting over 1 million miles on the road, or 20 years if used in grid energy storage.

Looking at these initiatives, as well as the battery pack contingencies outlined in the recently released patent, it appears that Tesla is building up towards creating an ecosystem of products that are capable of lasting decades. This, of course, plays a huge part in pushing Tesla’s overall goal of accelerating the advent of sustainable energy.

<!–

–>